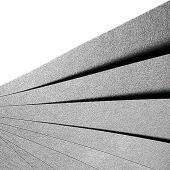

AIDA titanium filter cartridge is based on pure titanium powder(Purity 99.7% or higher) as the main raw material. After high heating sintering, it appears uniform structure and high density pores. It also has great filtration precesion and high flow rate. It can be used for solid liquid, gas seperationand purification. The perfect strength and titanium media makes it is able to withstand harsh high temperature and pressure working environments.

A titanium powder sintered porous filter provides stable separation efficiency during the filtration process. The filter is made from titanium powder without the addition of any binders. Firstly, the titanium powder is compacted and shaped at room temperature using a liquid as the pressure medium. Subsequently, high-temperature vacuum sintering takes place. At temperatures below the melting point of the titanium powder, physical and chemical interactions, such as particle bonding, occur between the particles, resulting in a sintered material with the required strength and properties. Equipped with various connectors, the titanium powder sintered porous filter maintains a stable shape, excellent breathability, and superior separation efficiency.

The pore size, distribution, strength, and breathability of the titanium powder sintered porous filter are dependent on the powder fineness, compaction, and sintering process. The titanium powder sintered porous filter achieves micro-level fine filtration, effectively removing solid particle impurities from both liquids and gases.

The filter is made from 99.7% titanium powder and exhibits characteristics such as low density, high strength, excellent corrosion resistance, and good biocompatibility. It offers filtration precision ranging from 0.45 to 100μm.

The titanium powder sintered filter can be used with various types of connectors and can be customized according to specific requirements. Here are some common connector types:

Standard connector: Including 215, 222, and 226 connectors, which are typically used in industrial filtration equipment and filter cartridges.

Thread connection: Such as M20, M30, M32, M42, and other types of threaded connectors, used to connect with other equipment or pipelines for more convenient filtration operations.

Flat/DOE: These connectors have a smooth surface and are suitable for certain specialized filtration applications.

Special Customized Connectors: Different types of connectors can be custom-designed based on users' specific needs and special applications to ensure the effective operation of the filter in specific environments.

Technical parameter

Cartridge structure |

Filter media |

Titanium powder |

Seal ring material |

Silicone,Viton,EPDM,PTFE |

|

Working situation |

Max.working temperature |

≤200℃ |

Max. working pressure drop |

300Mpa/23℃ |

|

Rating |

0.45, 0.5, 1, 2, 5, 10, 20, 50, 75, 100 micron |

|

Length |

125, 250, 350, 500, 750, 1000 mm |

|

OD |

20, 30, 50, 60, 70, 90mm |

|

Connector |

M20 M30 M32 222 226 |

|

The flexibility provided by these connector types makes the titanium powder sintered filter suitable for a wide range of industrial and laboratory filtration needs.

اللغة العربية

اللغة العربية বাংলা

বাংলা German

German Français

Français Bahasa

Bahasa Italiano

Italiano Nederlands

Nederlands Português

Português Русский язык

Русский язык Español

Español Türkçe

Türkçe