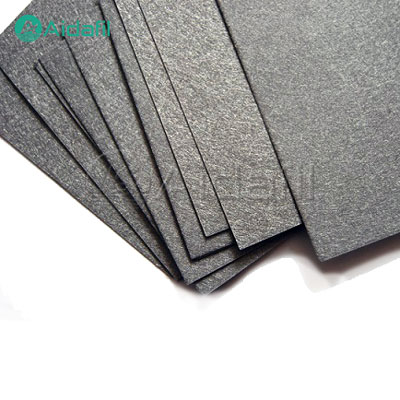

What is Sintered wire mesh?

Sintered wire mesh is made of multi-layer metal braided wire mesh through special lamination pressing and vacuum sintering. It is a new filter material with high mechanical strength and integral rigid structure, the mesh holes of each layer are interlaced with each other to form a uniform and ideal filter structure.It not only overcomes the shortcomings of low strength, poor rigidity and unstable mesh shape of ordinary metal wire mesh, but also can reasonably match and design the pore size, permeability and strength characteristics of materials. So it has excellent filtration precision, filtration impedance, mechanical strength, wear resistance, heat resistance and processability. At present, the series of multi-layer sintered metal mesh products developed and produced by our Aida company has been widely used in the fields of filtration and purification, gas-solid, liquid-solid and gas-liquid separation, divergent cooling, gas distribution, air floatation transfer, fluidized bed, gas sample collection, shock absorption, silencing, flame retardant and so on.

What is the specifications of Aida Sintered wire mesh?

The standard material is SUS304 (AISI304) / SUS316 (AI-SI316) / SUS316L (AISI316L), which can also be customized for special alloys such as Hartstone, Monel, Inconel, etc.

Standard size: 500*1000mm、600*1200mm、1000*1000mm、1000*1200mm

Filtering accuracy:1-300um

Aperture ratio:37%;

Gram weight:8.4kg/m2

Pecial specifications can be supplied according to the requirements of the buyer.

Specifications of Sintered Wire Mesh |

|||||||

Model |

Nominal Filter Rating (um) |

Structure Protective Layer + Control Layer + Dispersion Layer + Reinforce Layer + Reinforce Layer |

Thickness |

Air Permeability (L/min/cm2) |

Bubble Pressure (mm H2O) |

Weight (kg/m2) |

Porosity (%) |

SM5-1 |

1 |

100 + 400 × 2800 + 100 + 12 × 64 + 64 × 12 |

1.7 |

1.81 |

360-600 |

5-layer sintered wire mesh(8.4) 6-layer sintered wire mesh (14.4) |

40% |

SM5-2 |

2 |

100 + 325 × 2300 + 100 + 12 × 64 + 64 × 12 |

1.7 |

2.35 |

300-590 |

||

SM5-5 |

5 |

100 + 200 × 1400 + 100 + 12 × 64 + 64 × 12 |

1.7 |

2.42 |

260-550 |

||

SM5-10 |

10 |

100 + 165 × 1400 + 100 + 12 × 64 + 64 × 12 |

1.7 |

3.00 |

220-500 |

||

SM5-15 |

15 |

100 + 165 × 1200 + 100 + 12 × 64 + 64 × 12 |

1.7 |

3.41 |

200-480 |

||

SM5-20 |

20 |

100 + 165 × 800 + 100 + 12 × 64 + 64 × 12 |

1.7 |

4.50 |

170-450 |

||

SM5-25 |

25 |

100 + 165 × 600 + 100 + 12 × 64 + 64 × 12 |

1.7 |

6.12 |

150-410 |

||

SM5-30 |

30 |

100 + 450 + 100 + 12 × 64 + 64 × 12 |

1.7 |

6.7 |

120-390 |

||

SM5-40 |

40 |

100 + 325 + 100 + 12 × 64 + 64 × 12 |

1.7 |

6.86 |

100-350 |

||

SM5-50 |

50 |

100 + 250 + 100 + 12 × 64 + 64 × 12 |

1.7 |

8.41 |

90-300 |

||

SM5-75 |

75 |

100 + 200 + 100 + 12 × 64 + 64 × 12 |

1.7 |

8.7 |

80-250 |

||

SM5-100 |

100 |

100 + 150 + 100 + 12 × 64 + 64 × 12 |

1.7 |

9.1 |

70-190 |

||

SM5-150 |

150 |

50 + 100 + 50 + 30 + 30 + 100 + 50 |

2.0 |

25.00 |

50-150 |

||

SM5-200 |

200 |

40 + 80 + 40 + 20 + 40 + 80 + 40 |

2.0 |

26.00 |

50-150 |

||

What are the features and benefits of Aida Sintered wire mesh?

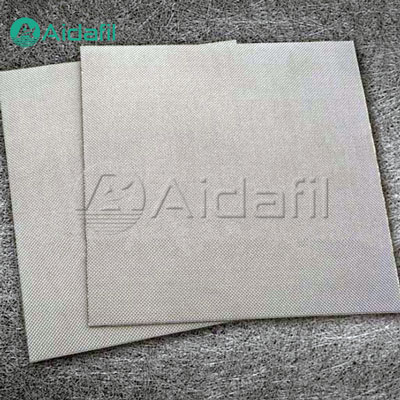

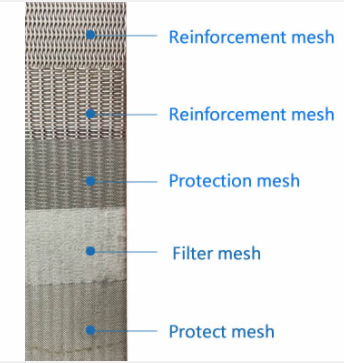

The most commonly used sintered mesh is the standard five-layer sintering

mesh. Its structure and characteristics are as follows:

The standard five-layer sintered mesh consists of a protective layer, precision control layer, dispersed layer and a multi-layer reinforcement layer.

Filter mesh not easy to deform because of two protective layers.

Can used for uniform filtration in high pressure or high viscosity environment.

Suits for cutting, bending, punching, stretching, and welding

High-strength: After the five layers of wire mesh are sintered, the mechanical strength and compressive strength are very high.

High-accuracy: The filtration granularity of 1-100um can play a uniform surface filtration performance.

Heat resistance: Resistant to continuous filtration from -200 to 600 degrees.

Cleanliness: Because of the excellent surface filtration structure with excellent reverse flow cleaning effect, simple cleaning .(It can be cleaned by reverse flow of water, filtrate, ultrasonic, melting, baking, etc.)

Do you know Production process of Aida Sintered Wire Mesh?

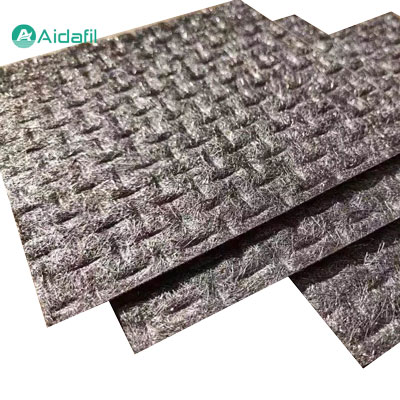

A. Select stainless steel wire woven mesh

According to the type of wire mesh selected and the stacking structure, five kinds of sintered meshes with strong corrosion resistance and large filtration range (1-200um) can be made, namely: five-layer sintered mesh, punched plate sintered mesh, square hole sintered mesh Sintered mesh, multi-layer metal sintered mesh and mat type sintered mesh.

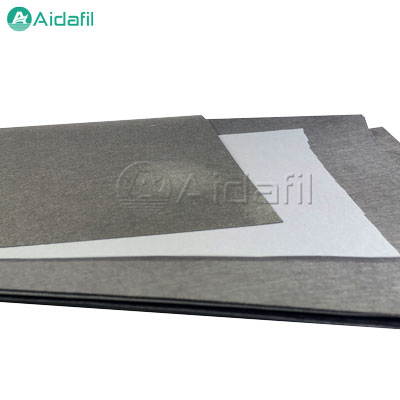

B. Sintering, pressing, vacuum sintering to 1100℃

Sintering and pressing can make each layer of stainless steel wire mesh stick and fuse together, with high mechanical strength and overall rigidity, and easy processing (cutting, stamping, bending, welding).

C. Diffusion solid solution

After the temperature reaches 1100°C, the process of diffusion and solid solution is adopted, so that the mesh channels are not easily deformed and smooth. Therefore, the sintered mesh not only has the advantages of stable filtration accuracy and easy cleaning, but also is suitable for complex environments with high temperature or low temperature from -200°C to 480°C.

How to Clean Aida Sintered Wire Mesh?

The most commonly used methods are physical and chemical.

Physical method

A. Ultrasonic cleaning

B. Backwash with cleaning gas

C. Cleaning liquid recoil.

Chemical method

A. Using diluting acid or alkali

B. Using surfactant, oxidizer, and other suitable agents

Note: After cleaning, we advise checking its integrity and measure pressure drop by a bubble point test.

What Applications use Aida Sintered Wire Mesh?

Precision filtering of various hydraulic oil lubricants in mechanical industry.

Filtration and purification of polymer melt in Chemical fiber film industry, petrochemical industry in various high temperature, corrosion liquid filtration, pharmaceutical industry materials filtering, washing, drying.

Application of Gas homogenization in Powder Industry, Sulfur plates in the steel industry.

Sound splitter in explosion-proof electrical appliances.

Depending on your unique specifications, Aida offer the perfect solution for all sintered wire mesh.

Contact us now for the best prices on sintered wire mesh. Our expert technical team can be 24/7 for you!

-

316L Fecral Sintered Metal Fiber Felt Filter plate for medicine

-

China Henan Xinxiang Porosity Sintered Fiber Felt Filter Disc Plate

اللغة العربية

اللغة العربية বাংলা

বাংলা German

German Français

Français Bahasa

Bahasa Italiano

Italiano Nederlands

Nederlands Português

Português Русский язык

Русский язык Español

Español Türkçe

Türkçe